In September of 2024, I joined Cal Poly Prototype Vehicles, or PROVE for short. After completing my recruitment project, the next project I had was on a vehicle named MILA, an all-electric endurance vehicle designed to surpass the driving range of any commercially available EV and eventually break the Guinness World record for longest distance travelled on a single charge. I chose to research LiFePO4 due to the energy density, cost, chemical stability, and commercial availability of this cell chemistry.

Compared to other cell chemistries such as LiCoO2 (Lithium Cobalt Oxide), the most common Li-ion cell chemistry type, LiFePO4 is comparably much more stable.

Compared to newer cell chemistries such as Solid State, LiFePO4 is a comparatively more mature cell chemistry that has been around since the 90s.

Prismatic vs Cylindrical. The advantages of Prismatic is that because of its rectangular prism shape, it’s easier to pack together and create mounting structures for them. The disadvantage and advantage of cylindrical cells is that the packing is less efficient, making for a less overall energy dense battery pack but allowing for the potential of more airflow to aid in cooling.

One of the main vendors I checked out was 18650batterystore.com, which is where I have historically used in the past to look at battery datasheets during my time in Cal Poly Racing. I took the available LiFePO4 cells and imported them into an Excel sheet which ranks parameters by cost, energy density, mass, voltage, current———- color coded

The search quickly narrowed down to the Prismatic cells since the two cylindrical cells that were offered by the vendor were not energy efficient nor were they cost-effective.

The EVE LF105 Prismatic Cell was the one that I decided on.

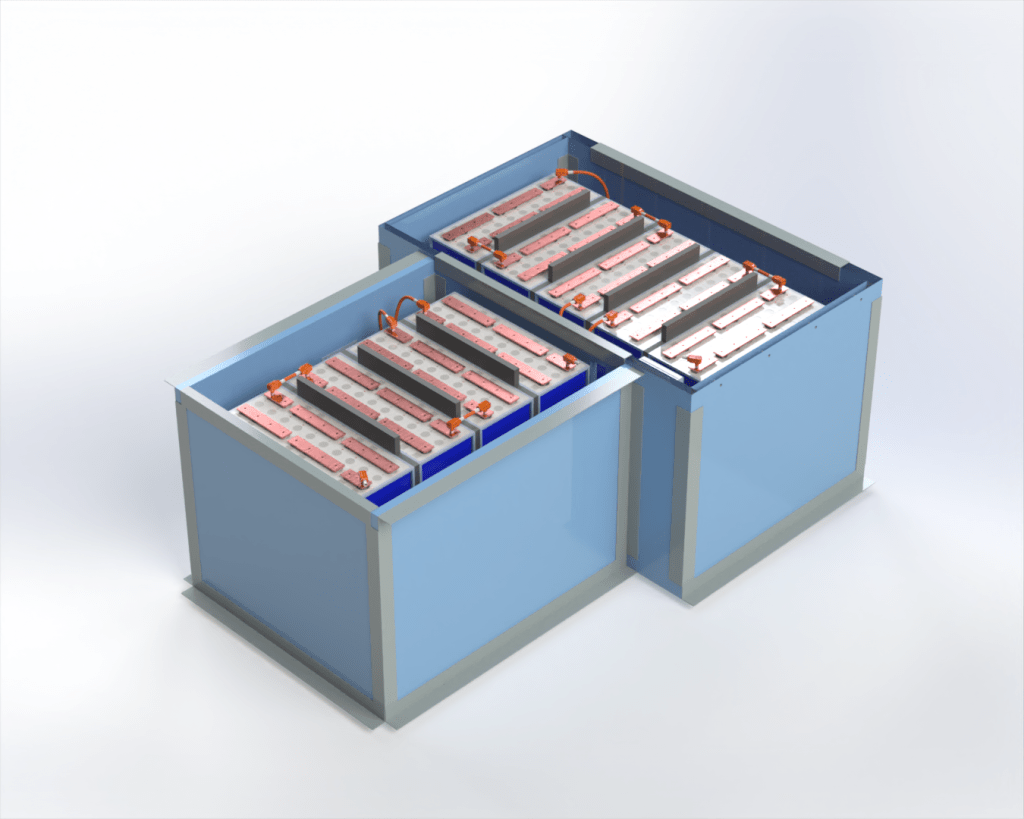

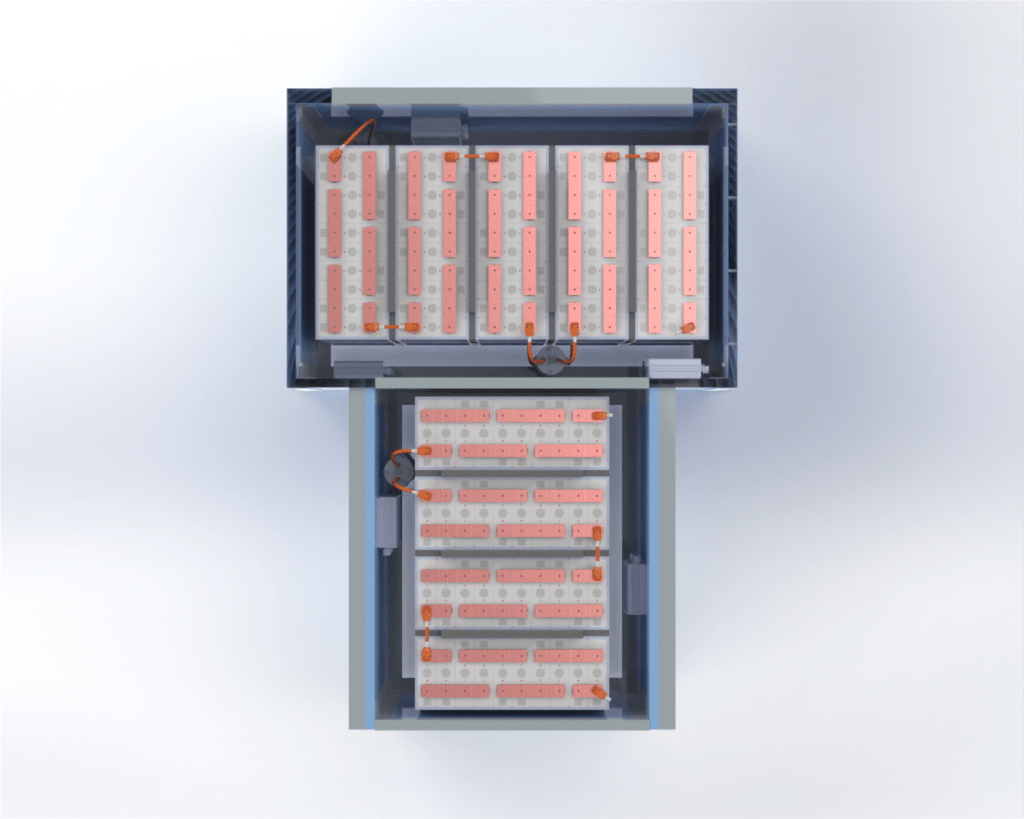

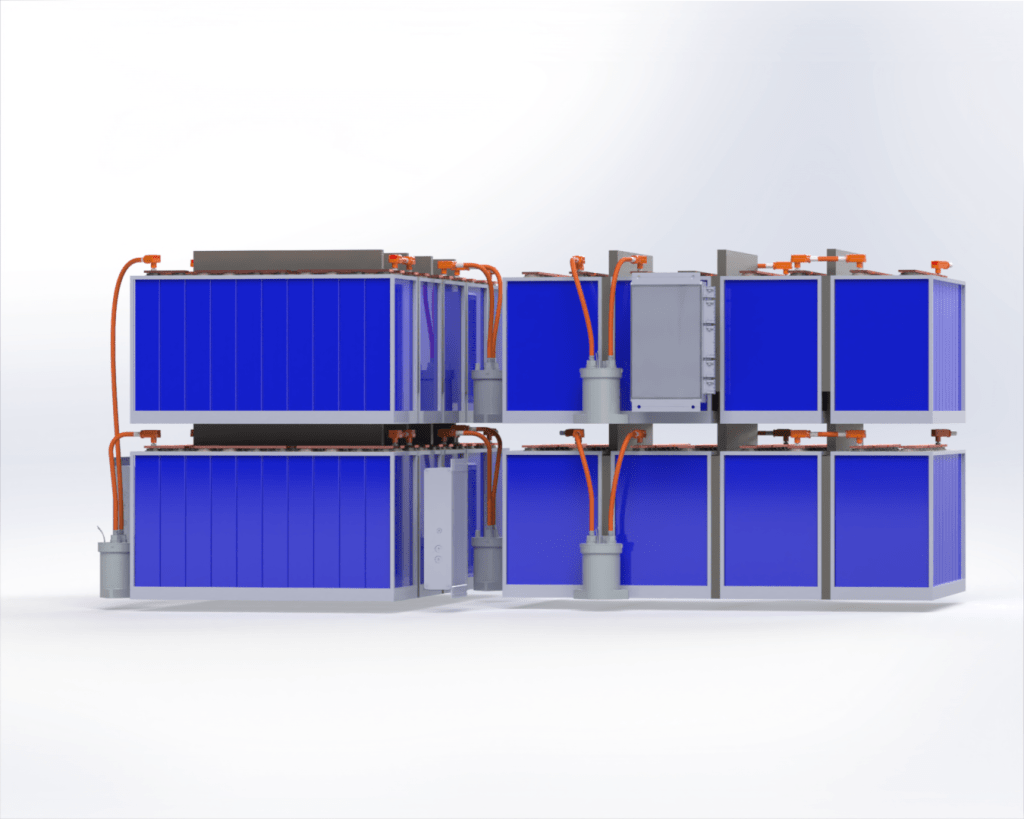

Since the previous battery box had already been constructed for a different cell chemistry, the integration of this cell was dependent on the pre-existing size of the small and large battery box.

As of December of 2024, the battery box is currently in the hands of the mechanical team to figure out mounting structures and plates for the cell modules, BMS, contactors, etc. since that is realistically out of my scope as an Electrical Engineer.

The team has conducted some thermal simulations with this battey pack which predicts a fairy low heat output, given the low power draw that is expected for a vehicle designed for mileage. There is a plan to purchase a few of these LF105 cells to conduct some steady-state thermal analysis using some kind of load, preferably a DC Electronic Load.